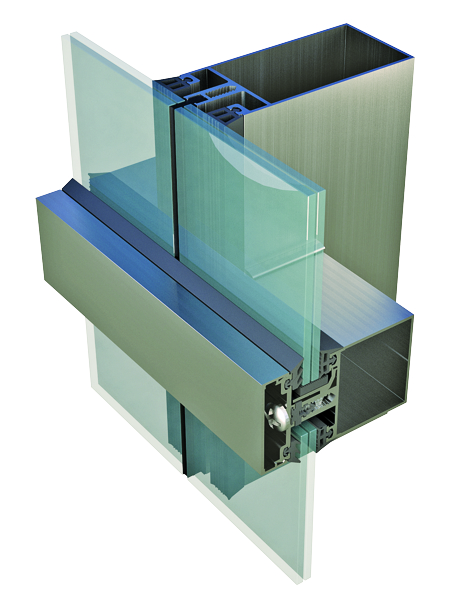

Stick curtain wall system, with controller pressure chamber (isobaric chamber), corresponding to the fifth generation of wordwide developed curtain walls. It is composed by cut to lenght and machined in factory transoms and mullions, connected by the use of internal unions, which are assembled to the mullion, guaranteeing water conduction. Additionally, the EPDM or silicone gasket system reduces the on-site sealant use, providing a high installation rate.

Xavierian University – Bogotá D.C.

Each module is fully assembled and installed with Ss304 stainless steel screws. The tridimensional anchorage system allows the curtain wall to support +/- 25 mm plumbness tolerances, +/- 6mm in level alignment and +/-40 mm vertical misalignment, reducing and facilitating levelling works done in the construction site, resulting in fast and optimal solutions to any installation requirement and allowing tridimensional levelling of the facade.

The profiles are sealed each other by a gasket system which controls the water entrance and conduction to the exterior weeping system, providing R650 level for water penetration in curtain walls, according to ASTM E331 and EN 12208 and C3 level for structural performance according to ASTM E330 and EN 12207.

Classic

visible mullions and transoms

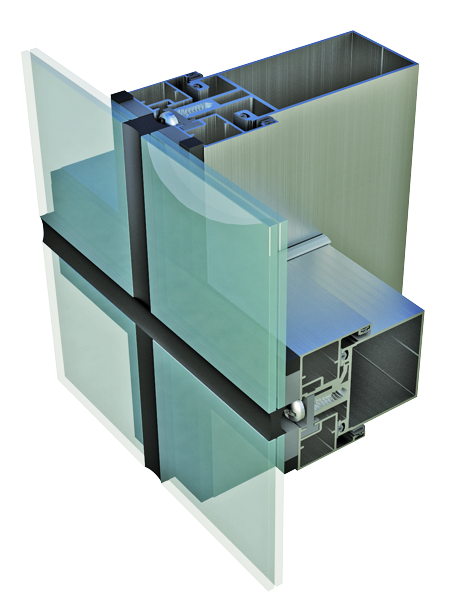

Hidden

hidden mullion

visible transoms

Silicone Glazed

structural silicone

glazed modules

PROFILES

The Svelte 50 curtain wall system allows the use of different transoms and mullions, obtaining the same weather and structural performance, with different configurations, in order to achieve up to 2.0 kN/m2, windloads in 5.30 m heights, becoming an architectural design friendly solution.